This article outlines false alarms, how to diagnose the root cause and how to resolve them.

What are false alarms?

False alarms are alarms you will receive not because your equipment is experiencing a deviation in condition, but because of other factors such as installation issues that are causing the data the FitMachine is receiving to change.

The main reasons false alarms are triggered include:

- The FitMachine has been moved

- The Running Cut-Off has been set incorrectly

- The FitMachine has not been attached securely

- Production changes have occurred previously unseen by the FitMachine, or

- The FitMachine's learning has not been recalibrated in years.

Why are false alarms important?

False alarms are an indication that you need to review your FitMachine's setup. It's important that if you receive a false alarm, you take action. Left unresolved, false alarms will continue to be triggered. This will result in decreased productivity on your behalf, and you may miss real, valid alarms.

What to do with false alarms

Once you determine you have received a false alarm, and see no equipment-related explanation for the deviation in condition, the most important thing to do is work out why the alarm was triggered.

The most obvious cause would be production changes that the FitMachine did not learn to be 'normal' during its calibration period. In this case, if the production change is permanent, you will need to reset your FitMachine's learning period.

Otherwise, if the equipment's condition has not changed for the worse, that means the issue is linked to your FitMachine and its installation.

The FitMachine has been moved.

If the FitMachine has been moved, the condition data FitMachine is reporting is likely to change. This is because the FitMachine will now be in a different place on the equipment and likely receiving different levels of vibration, temperature, tone and frequency data.

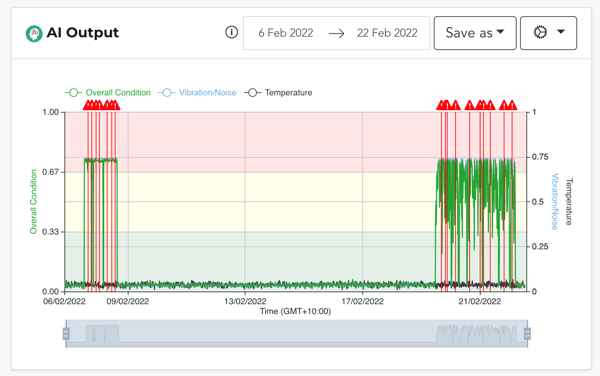

You can identify this on your dashboard as if the FitMachine has been moved, the running pattern displayed on the dashboard will permanently change.

.png?width=600&name=image%20(1).png)

This can be resolved by moving it back to its original position, or if not possible, restarting the learning of your FitMachine.

The Running Cut-Off (RCO) has been set incorrectly.

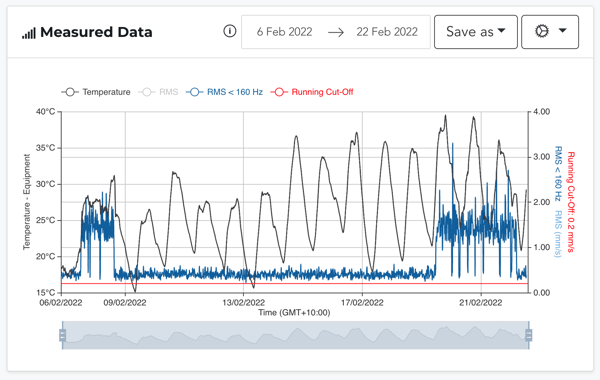

If your RCO has been set incorrectly, your FitMachine may be reporting non-running data. This will be the case if your RCO has been set lower than the equipment's running vibration pattern, and will mean your FitMachine thinks your equipment is running when it's actually off (see example below).

This can result in false alarms being triggered each time your equipment is turned on.

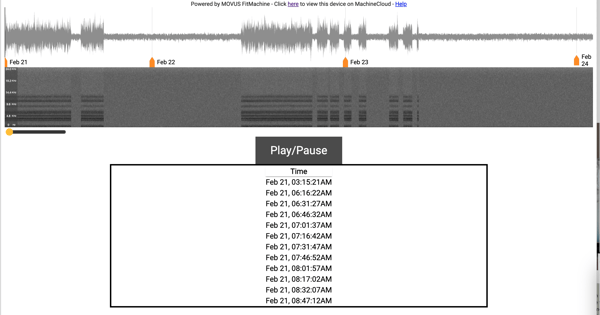

To help reaffirm the assumption that your equipment isn't running, you can use your Time Waveform Diagnostic which plays back the accelerometer output of your machine.

Compare the running pattern to what the machine is meant to be doing, and see what your RCO has been set to, to identify if this is the case.

To resolve this, please read our article Adjusting the Running Cut-Off.

The FitMachine has not been attached securely.

If during the FitMachine's initial installation, the magnet was not mounted securely on a flat, clean surface, it may rock around and move, introducing a lot of noise to vibration data and making it very difficult to provide an accurate picture of the health of your equipment.

The standard FitMachine magnet is designed with a groove to assist with rounded surfaces, however, the sensor can still sit unsteadily if not mounted properly.

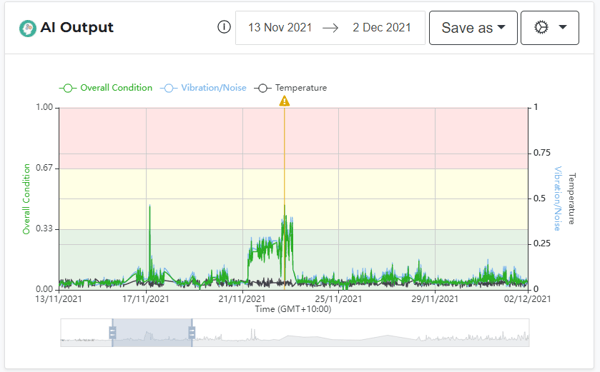

This is often visually identifiable through inconsistent and unstable data such as the image below.

You can test if this is the case by giving the FitMachine a gentle wiggle in a couple of different directions and feeling for a small rocking movement. If so, relocate the FitMachine where necessary and restart learning.

The FitMachine's learning has not been recalibrated in years.

If your FitMachine has been installed for a couple of years, the condition data received by the equipment may have slowly changed over time to the point where what's considered 'normal' now may be a large difference to what was normal during installation and thus be triggering alarms.

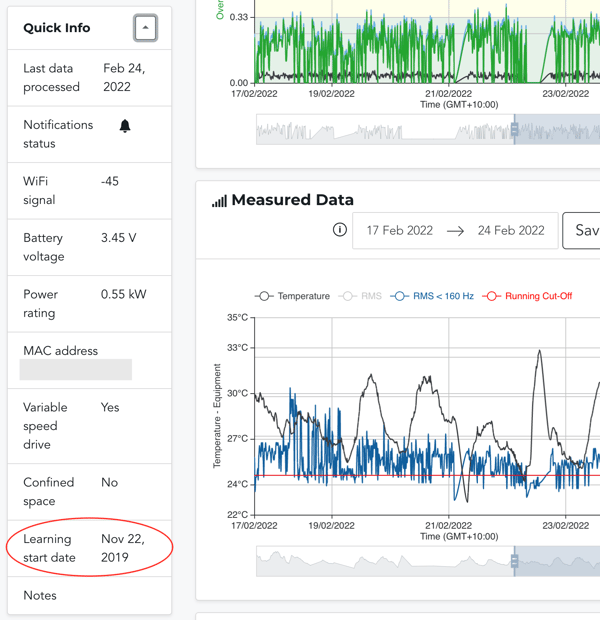

You can identify when your FitMachine was recalibrated on the Equipment Detail Page by viewing the noted Learning Start Date under the Quick Info tab.

This will become clear by comparing recent and old data. If this is the case, set the FitMachine to relearn.

What else should I look at?

- What to look for in MOVUS Alarms

- How to Respond to MOVUS Alarms

- Understanding Measured Data Alarms

- About FitMachine Sensor Installation

- Restart Learning of a FitMachine

---

If you have any questions, or if you are receiving false alarms not caused by these issues, please reach out to MOVUS Support here!