This article details the best practice for FitMachine installation in general terms.

FitMachine installation is important as you will get more value from the system with a well placed FitMachine on each of your equipment.

However, installing your FitMachine sensors is very easy and requires no tools. To ensure the best possible installation, some guidelines are provided below to help you.

1. Radial to the shaft of the fixed rotating asset

By this, we mean the location of the FitMachine is preferred to be on the side of the equipment. If this isn't possible then on top of the equipment. The FitMachine should not be on the end of the equipment. A radial location is recommended because most of the forces from faults are directed in that direction from the shaft.

2. Close to the source of vibration

Being closer to the source of vibration (above a bearing) reduces the transmission path for the vibration and improves the data quality.

3. Single Point of Contact

Make sure the magnet is the only point of contact between the FitMachine and the equipment to receive the best data and insights into the health of your equipment. Always avoid multiple points of contact where possible, as it will introduce noise into the signal.

4. Secure Attachment

Be sure to check the FitMachine is mounted securely on a flat surface to receive clear and accurate data. The cleaner the surface, the better.

If the FitMachine rocks around when installed it will introduce a lot of noise to vibration data making it very difficult to provide an accurate picture of the health of your equipment. Test this by giving the FitMachine a gentle wiggle in a couple of different directions and feeling for a small rocking movement and relocate the FitMachine where necessary.

5. Driven Equipment rather than Motor

To get the most out of your FitMachines, MOVUS suggests installing the sensors on the drive end of the equipment rather than the paired motor. This is because the equipment the motors are coupled to generally show signs of failure earlier and more often due to an increased number of failures modes.

However, if the motor is the asset you're interested in, MOVUS suggests installing it on the drive end to gather as much feedback from the coupled equipment as possible.

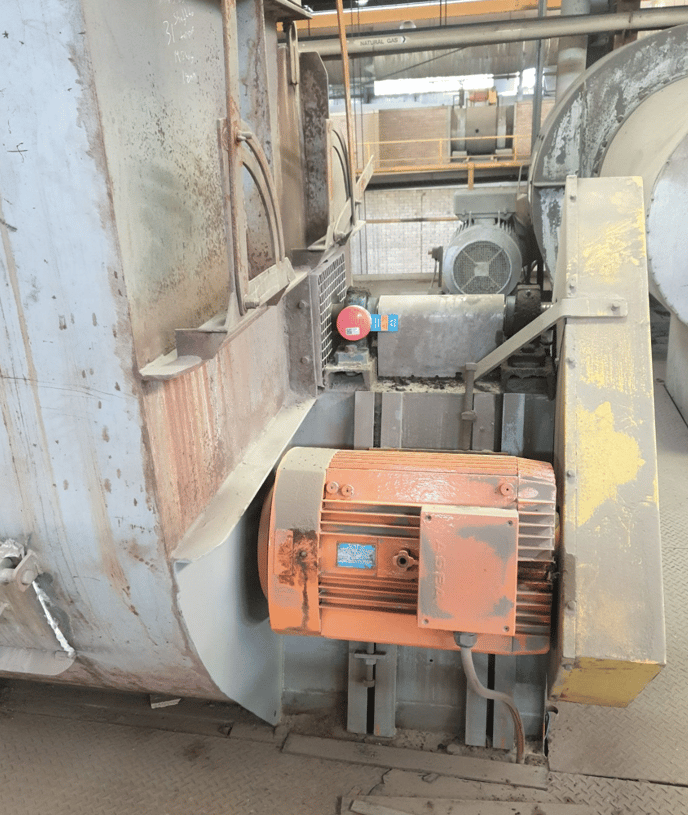

The photo below is an excellent example of a well-installed FitMachine with the blue MOVUS swing tag.

What else should I look at?

---

Thanks for reading. If you wish to discuss with us a specific case about where to place a FitMachine, please contact MOVUS Support here.