This article outlines how you can optimise your FitMachines to best monitor variable processes and minimise false alarms.

How can it help you?

If asset/s are alarming regularly, this may be due to a process or operational change that the MOVUS Al has not previously seen or learnt to be 'normal'. Shifting to run a production line at 120% or processing a different material, for example, will make an asset vibrate in a different way and can result in a condition change detected by the AI.

Whilst you may ignore alarms on specific assets when they are believed to be related to a process change, ignoring alarms may result in missing a potential issue. Hence, to ensure your FitMachine/s can accurately and reliably monitor your equipment, and to prevent alarm fatigue, we recommend that you update your FitMachine/s learning period to optimize the Al for additional variable processes.

How does it work?

As FitMachine is designed to send alarms when your equipment's condition deviates from its learned 'normal' operating behaviour (as established during the FitMachine Learning Period), you will receive 'false' alarms if production changes occur, previously unseen by the FitMachine, that cause the data the FitMachine is receiving to change.

To avoid this, there are two actions you can take:

- If the operational change is permanent, or if you're going to be operating in a new way for a number of months, you can restart learning.

- If the process change is a normal, regular occurrence for that asset, you can edit the learning start date for that asset and have the FitMachine learn the change to be part of the asset's 'normal' operating behaviour.

Restarting Learning

If the production change is permanent, you will need to Restart Learning. Restarting Learning initiates an accelerated learning period, in which the FitMachine will collect 5000 running samples for the AI to use to build new models and learn the new pattern of the equipment. During this accelerated period, FitMachine will sample every minute, so this process will usually take around two weeks. However, this may take longer as running samples are required, and hence if a machine isn't running for a period of time, FitMachine won't see it as a sample.

Regardless, during this period, the FitMachine can begin alarming again once it has collected at least 1000 samples. However, it will take a significant change for the FitMachine to alert up until the 5000 running samples are collected.

How do I Restart Learning?

How to restart learning is outlined in our article Restart Learning of a FitMachine.

Editing Learning Start Date

To have your FitMachine learn the process changes to be 'normal', you will need to edit the learning start date for that asset. This allows you to go back in time and change the date on which the FitMachine initiated its learning period. This is significant because it means you can choose a point in time during which the equipment was running multiple processes, and have FitMachine use that data to create new models.

Hence, by editing the learning start date, your FitMachine can relearn using a window of time that captures all the processes that run on that equipment, and establish that as it's 'normal'.

As long as there are already 5000 running samples from the new learning start date, then this relearning period will only take a day or two. This will not impact your FitMachine's functionality. It will continue to function and alarm whilst it relearns.

If the new start date means there are less than 1000 data samples it won’t alarm until it has at least 1000 samples. If there are less than 1000 samples, it will speed up the sampling rate until 1000 samples are reached (just like a newly onboarded FitMachine). If there are more than 1000, your FitMachine will sample every 15 minutes until 5000 running samples are collected. Depending on the utilisation of your asset, this may take anywhere between a few weeks to a few months.

How do I Edit the Learning Start Date?

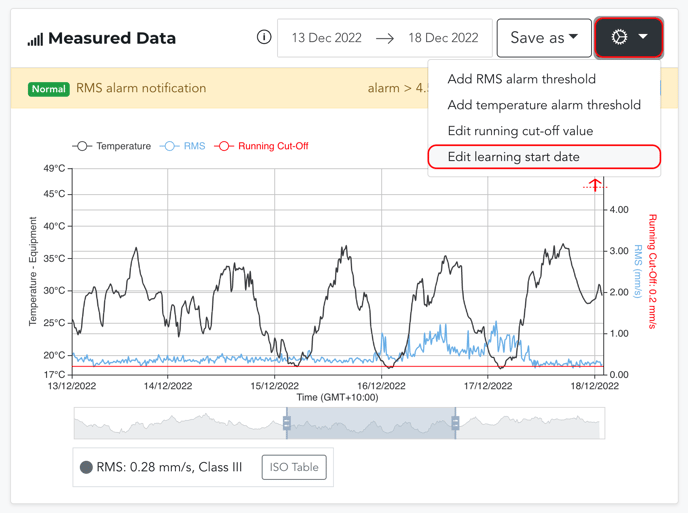

To edit the learning start date, you will need to access the Measured Data Chart for that asset on its Equipment Detail Page. Clicking the cog in the top right corner allows you to access this functionality. Once you have selected 'edit learning start date', you can use the calendar feature by clicking on the visible dates to make this process easier.

- About the FitMachine Learning Period

- Restart Learning of a FitMachine

- Understanding the Measured Data Chart

---

Thanks for reading. As always, if you have any questions or concerns please reach out to MOVUS Support here.