The Running Cut-Off is of critical importance to the FitMachine AI, reporting interval and data generally. Please ensure that it is set correctly for each FitMachine sensor that you have deployed.

How can it help you?

The Running Cut-off is a vibration (mm/s or in/s) value assigned to a piece of equipment/FitMachine sensor that will assist in separating running samples from ambient noise and vibration. This helps you by ensuring that the FitMachine sensor learns from data gathered while the equipment is running which is critical to the FitMachine AI.

It also helps ensure that the FitMachine sensor is reporting at the correct intervals. When the equipment is not running the sensor samples less often to save battery. If the Running Cut-off is too high then the sensor won't gather enough samples, too low and the sensor will be gathering non-running data which will use battery unnecessarily.

Without the correctly set Running Cut-Off the FitMachine sensor won't gather data at the right times and it will significantly reduce the effectiveness of the FitMachine AI.

How does it work?

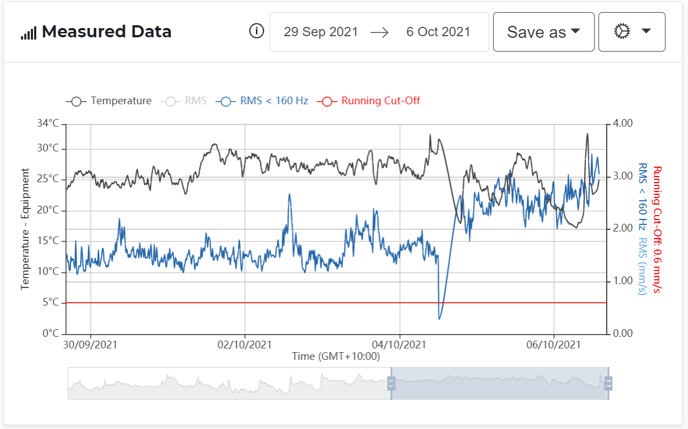

The Cut-off is indicated by the red line on the Measured Data Chart and the value is given to the right of the chart, shown below.

This line is used to determine which samples are from running equipment and is of critical importance to the MOVUS AI. The Running Cut-off must be correctly set in order for the learning process to be completed properly. Otherwise, the 'normal' running operation that has been learned will not be an accurate representation of your equipment.

This line is used to determine which samples are from running equipment and is of critical importance to the MOVUS AI. The Running Cut-off must be correctly set in order for the learning process to be completed properly. Otherwise, the 'normal' running operation that has been learned will not be an accurate representation of your equipment.

Incorrect placement of this line will also have an effect on the data shown in the Utilisation chart, the Inferred power usage calculation as well as the machine running indicator. Therefore, it's once again worth saying that it is of critical importance that the Running Cut-off is correctly positioned for each piece of your equipment.

By default the Running Cut-off is set at 0.6 mm/s for all newly onboarded sensors which we have found is generally a good position to start for standalone equipment.

For some installations where there are multiple pieces of equipment linked to the same process, such as the 3 pumps shown in the photo below, the vibrations from one pump can be detected by a FitMachine installed on one of the adjacent pumps. Adjusting the Running Cut-off gives you the ability to isolate the vibration of one piece of equipment from another by setting the cut-off high enough to ignore the vibrations that are being inferred through the ground or pipes in some cases.

What else should I look at?

- Adjusting the Running Cut-Off

- Understanding the Running Status

- Introduction to FitMachine: This gives you a summary of how the system works

- Knowledge Base Structure: This tells you where to find things within this knowledge base

---

Thanks for reading. As always, if you have any questions or concerns please reach out to MOVUS Support here.